Last post, we shared how tool steel is hardened and also how soft metals can “mushroom” from use on the fire ground and in trainings. This post, let’s take it a step further and talk about caring for your tools. You are professionals in the fire service. Being professionals (career or volunteer) means attention to detail and caring for your equipment, i.e. maintaining the tools on your apparatus so they are combat ready. Rusty tools say a lot about a fire company. Let’s be honest, if you have rusty tools as you walk past the Chief at a fire, your crew might not care about going to fires or much less the job. Clean well-kept tools say it all… you care about the job and you have pride in your equipment! That being said, we can’t fault those who were never taught or learned why clean tools are important. So here at Leatherhead Tools, we want to share and pass on what we know about cleaning tools. Remember, everything we are sharing here is what we’ve learned from fire service professionals, and they are some of the best! The following is not “the” way… it’s just “a” way and if you have something better, p-l-e-a-s-e comment on this post, share it with us by email, and send some photos along with! You can even enter your story into our Firefighters Wanted! Program.

We used an Ultra Force Axe that we let sit out in the elements for a while to get good and rusty specifically for this post.

The first step for something that’s in this bad of shape is to crank up the tunes, because you are going to be here for a few minutes. Next power up that that bench grinder with a wire wheel or an angle grinder using a fine grit flap disc to get rid of the rust and metal burs. We used a 120-grit flap disc that had cooling technology to help prevent overheating and damaging the temper of the metal. If there is a lot of mushrooming or burs on the tools grab a flat file and use that to file metal away.

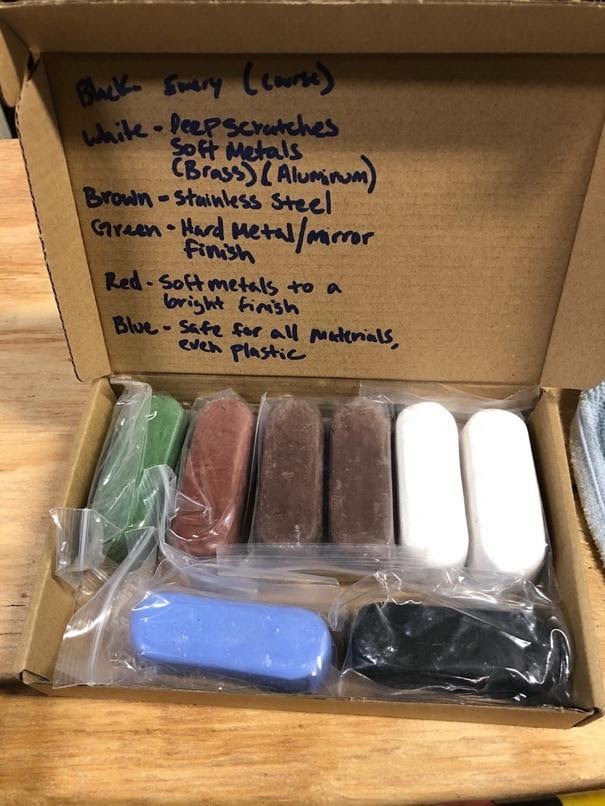

After the 120-grit flap disc, we took it a few steps further using a few felt buffing discs with metal buffing compounds. We bought a compound bar set and a stack of felt discs off Amazon that worked great. You will want to dedicate one felt disc to each color bar, not mixing buffing compounds on one disc.

We used the green compound first to help clean up swirl marks from the 120-grit flap disc.

Then we switched felt discs and used the red buffing compound (sometimes referred to as a jeweler’s rouge) to get that bright shine. We don’t want a trophy axe finish but something we and service professionals are proud to swing!

After you get that axe or halligan looking good, don’t forget to put a thin layer of oil on the metal. Some people use WD-40 or JB-80 while others may use a gun oil or even carnauba wax to help protect the tool from the elements and prevent rust.

From here on out basic light cleaning with a fine grit emery cloth and WD-40 (wet sand technique) will help maintain the tools so they are battle ready without removing a lot of metal like a flap disc can.

A few end notes: our Halligans come coated in Zinc to prevent rusting and damage. We at Leatherhead Tools advocate that you don’t paint the axe heads or halligans as it can hide defects or stress fractures in the metal with use overtime. Thanks for reading our article and please send us your before and after photos of those tools!

Stay safe and train hard!

Copyright Leatherhead Tools | Made in America

Copyright Leatherhead Tools | Made in America